Minilab’s Sustainable Hydrofoils: LMPAEK™ Innovation

Introduction

In the demanding world of offshore racing, where marine composites are pushed to their absolute limits, a groundbreaking initiative is setting new standards for sustainability and performance. MiniLab, a pioneering real- world laboratory founded in 2023 in Lorient, France, has successfully developed recyclable hydrofoils using advanced LMPAEK™ thermoplastic composites – a technological breakthrough that earned recognition as a finalist at the 2025 JEC Composites Innovation Awards.

From Aerospace Innovation to Maritime Applications

LMPAEK™ Polymer History and Development

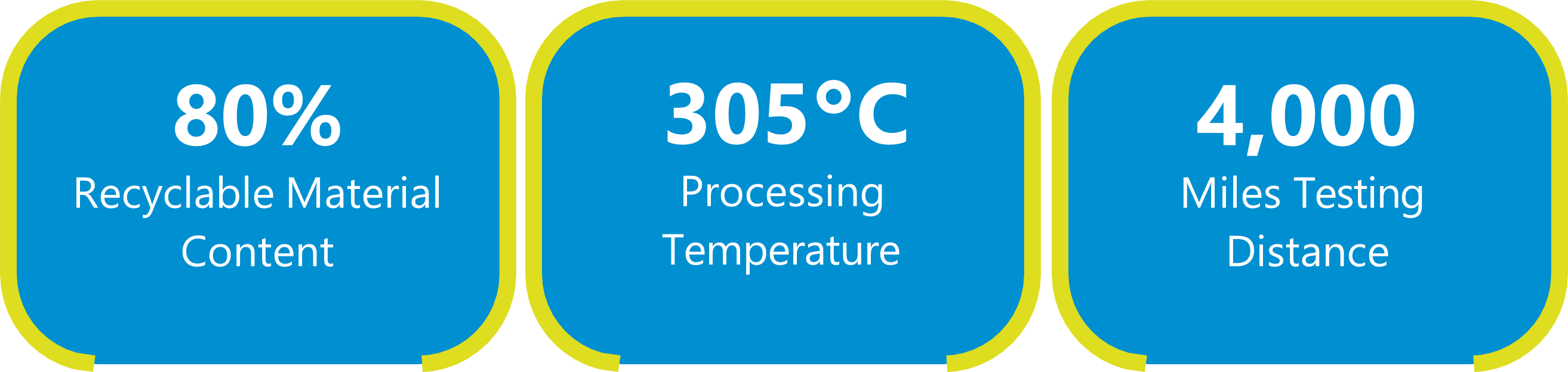

LMPAEK™ thermoplastic polymers were initially developed by Victrex more than a decade ago, originally gaining significant traction in the aerospace industry. Melting at 305°C (40°C lower than conventional VICTREX PEEK), these advanced materials offer performance attributes like PEEK with additional advanced manufacturing opportunities for sustainable maritime technology.

The aerospace adoption journey of LMPAEK™ polymers has been impressive, with several milestone achievements demonstrating their versatility across industries. Beginning with the CleanSky Programme collaboration in 2019, these materials have steadily gained recognition for their ability to facilitate high-speed automated fibre placement and enable the creation of complex structural components. These aerospace applications have enabled manufacturers to achieve critical weight reduction whilst maintaining exceptional mechanical performance, chemical resistance, and flame- retardancy properties.

Cross-Industry Technology Transfer Benefits

By 2022, key aerospace manufacturers were showcasing demonstrators at major industry conferences, highlighting the transformative manufacturing impact of these versatile materials. The trajectory continued with larger dimension parts and structures made entirely from LMPAEK™-based materials being showcased at industry exhibitions by 2023, earning prestigious recognition within the composite industry and demonstrating the maturity of the technology.

AVEL Robotics: Bridging Aerospace and Marine

The maritime application journey began when Victrex strategically identified alternative industries where LMPAEK™ polymers could solve pressing customer challenges. AVEL Robotics emerged from researching sectors with similar manufacturing requirements and an article in Composites World Magazine about hydrofoil development that highlighted a plant tour with Avel Robotics in Lorient, France. Avel Robotics was co‑founded by Luc Talbourdet and Adrien Marchandise.

The company began by adapting Automated Fiber Placement (AFP) for composite part production in the sailing industry. This striking parallel with aerospace manufacturing and processing unidirectional tape using automated fibre placement machines from Coriolis had similar manufacturing challenges. These challenges were time, speed, quality, efficiency, and throughput. There is also the universal drive to reduce costs while maintaining or improving performance.

While AVEL had investigated thermoplastics nearly a decade prior, high material costs had limited further development. Now, with the aerospace industry's increasing scalability and technological maturity driving down costs, the timing was ideal to re-engage with the novel LMPAEK™ polymer technology, bringing all the accumulated benefits from aerospace experience to maritime applications.

AVEL strategy is to utilise the agility of offshore racing to quickly develop expertise before transferring it to the aerospace sector. AVEL is already capable of producing thermoplastic parts with very low curvature radii. Learn more about LMPAEK™ polymers transforming the aerospace industry

Sustainable Hydrofoil Technology and Design

Revolutionary Approach to Marine Performance

Recyclable hydrofoils represent a revolutionary approach to sustainable marine performance. Hydrofoils are sophisticated wing-like structures that operate underwater, utilising complex hydrodynamic principles to generate lift as they move through water. This lift allows watercraft equipped with these foils to rise above the surface and glide with dramatically reduced drag, resulting in increased speed and fuel efficiency. Traditional hydrofoils, which are essential components for high-performance racing yachts and increasingly important for commercial vessels seeking efficiency gains, have historically relied on thermoset composites that present significant end-of-life recycling challenges and contribute to growing marine industry waste concerns.

The “Infinite Foil” Project Implementation

Led by Avel, the "Infinite Foil" project represents MiniLabs' initiative to unite diverse partners around a shared objective while testing components under real-world conditions. Through collaboration with key partners DIAB, Compositic, and Victrex, MiniLab has fundamentally challenged the status quo by demonstrating that sustainable maritime technology solutions can not only be achieved but can surpass the performance of conventional approaches. This ambitious project aimed to demonstrate that ocean sailing equipment could achieve sustainability goals without compromising the extreme performance demands of offshore racing through strategic implementation of VICTREX LMPAEK™ polymers.

LMPAEK™ Material Advantages

LMPAEK™ polymers represent a significant advancement in thermoplastic composite technology, offering an exceptional combination of properties that make them ideally suited for demanding maritime applications. Unlike conventional thermoset materials that undergo irreversible chemical changes during curing, LMPAEK™ thermoplastic composites maintain excellent mechanical strength and stiffness whilst introducing critical sustainability benefits including superior chemical resistance, outstanding fatigue performance, excellent impact strength, and most importantly for environmental concerns, complete recyclability at end-of-life.

Technical Specifications and Material Composition

| Property | LMPAEK™ Composites | Traditional Thermosets |

|---|---|---|

| Recyclability | 80% recyclable | Non-recyclable |

| Processing Temperature | 305°C | 180°C + curing |

| Reprocessing Capability | Multiple cycles | Single use |

| Production Time | Reduced cycle time | Extended curing required |

| Chemical Resistance | Excellent | Good |

Advanced Manufacturing with Automated Fibre Placement

Manufacturing Process Innovation

LMPAEK™ polymer technology offers significant manufacturing advantages that extend well beyond the performance characteristics of the finished product, fundamentally transforming the production process itself. The project utilises state-of-the-art automated fibre placement (AFP) technology for precise, computer-controlled layup of the thermoplastic composites, enabling unprecedented optimisation of fibre orientation patterns and achieving consistently superior part quality compared to manual layup methods. This advanced manufacturing approach demonstrates several transformative advantages over traditional thermoset manufacturing methods that have dominated composite production for decades:

-

Multiple Reprocessing Cycles: The thermoplastic nature allows materials to be reprocessed and reformed multiple times without experiencing the molecular degradation typical of recycled materials, maintaining structural integrity and performance properties through multiple lifecycle iterations

-

Dramatically Reduced Production Cycle Times: Manufacturing cycles are significantly faster compared to thermoset systems, eliminating lengthy curing processes and enabling higher throughput production capabilities

-

Eliminated Curing Requirements: The complete elimination of the time-consuming and energy-intensive curing process required for conventional composites reduces manufacturing complexity, energy consumption, and facility requirements

-

Zero-Waste Manufacturing Potential: Production waste and off- cuts can be directly repurposed and reintegrated into secondary structures or recycled back into raw material feedstock, approaching true circular manufacturing principles

-

Enhanced Design Flexibility: The ability to reheat and reform components enables post-manufacturing adjustments and repairs that would be impossible with thermoset materials

-

Reduced Tooling Costs: Lower processing temperatures and elimination of exothermic curing reactions reduce tooling wear and complexity requirements

Discover more about Victrex and Coriolis AFP collaboration

Performance Testing and Monitoring Systems

Advanced Structural Health Monitoring

The project's technical sophistication extends far beyond material selection to encompass comprehensive performance validation through advanced monitoring systems that validate LMPAEK™ polymer performance under extreme conditions in both controlled laboratory environments and challenging real-world ocean applications. Strategic partner company Pixel sur Mer has equipped the foils with specialised optical fibre sensors that provide continuous, real-time measurements of structural deformation, stress distribution, and performance parameters throughout testing and operational use.

Laboratory Testing and Validation Results

With the strategic partner Compositic, Comprehensive laboratory testing has already successfully validated the mechanical properties of the LMPAEK™ composite foils, confirming both their theoretical performance parameters and the effectiveness of the innovative manufacturing techniques employed. These controlled tests have demonstrated that the recyclable foils meet or exceed the performance benchmarks established by traditional thermoset alternatives across all critical metrics including flexural strength, impact resistance, fatigue life, and environmental durability.

Mini Transat 2025: Ultimate Real-World Testing

However, the ultimate validation will occur during the Mini Transat 2025 – a grueling Atlantic Ocean crossing covering 4,000 miles of the world's most challenging sailing conditions. This real-world testing environment will subject the recyclable hydrofoils to the full spectrum of conditions encountered in offshore racing, including varying sea states, temperature extremes, mechanical stress from wave impacts, and the corrosive marine environment over extended periods. The race represents the most demanding possible testing scenario for validating both the immediate performance and long-term durability of the sustainable composite technology.

Benefits of Recyclable Marine Composites

The transition to recyclable hydrofoils addresses critical environmental challenges facing the marine industry. Traditional composite waste from boat manufacturing and end-of-life vessels represents a significant environmental burden, with an estimated 1.5 million tonnes of composite waste generated annually in Europe alone.

Key environmental and economic benefits of LMPAEK™ marine composites:

-

Circular Economy Integration: Materials can be continuously recycled into new high-performance applications

-

Reduced Carbon Footprint: Lower energy requirements compared to producing virgin materials

-

Cost Efficiency: Elimination of disposal costs and material waste

-

Regulatory Compliance: Meeting increasingly stringent environmental regulations

-

Brand Differentiation: Supporting sustainability marketing and corporate responsibility goals

Adrien Marchandise and Gilles Larroque with LMPAEK™ Hydrofoils manufactured by Minilab at the JEC 2025 award exhibition

Future Applications in Marine Industry

Laboratory Testing and Validation Results

While the initial foils are sized for MiniLab’s Mini 6.50 racing yacht, the technology demonstrates substantial scalability potential. According to Marchandise, Avel Robotics has already launched a larger foil project, called foil infinity, funded by the region Bretagne and with MerConcept and Compositic as partners. The objective is to adapt the TP process to bigger structures like IMOCA/ULTIMATE foils which have a span of 5 to 10m. The target for manufacturing the first foils for ULTIM or IMOCA class racing yachts is by 2026 or 2027.

Cross-Industry Application Potential

The implications extend well beyond competitive sailing. The superior characteristics of LMPAEK™ polymers including excellent fatigue resistance, impact strength, and chemical resistance make them candidates for adoption in aerospace, automotive, and energy sectors where lightweight, high-performance, recyclable composites are increasingly in demand.

Maritime Industry Transformation Impact

This innovative application of LMPAEK™ polymers exemplifies how advanced materials science can address both performance and sustainability challenges simultaneously, creating pathways for more environmentally responsible approaches in high-performance applications.

For the maritime industry, which has traditionally struggled with end-of- life composite waste, the successful implementation of recyclable LMPAEK™ hydrofoils represents a significant stride towards more sustainable high-performance boating proving that environmental responsibility need not come at the expense of technical performance.

Read more on Minilab and their solution to sustainability challenges in offshore racing here. MiniLab provides a concrete solution to the sustainability challenges in offshore racing

Cross-Industry Impact and Recognition

The maritime application of LMPAEK™ polymers through MiniLab’s Infinite Foil project continues the impressive trajectory these materials have established across multiple industries. Since 2019, when Victrex collaborated with Toray on the CleanSky programme for the “Aircraft of Tomorrow,” LMPAEK™ polymers have steadily gained industry recognition through multiple JEC Innovation Awards and aerospace manufacturer showcases.

This cross-industry adoption demonstrates how technologies initially developed for aerospace can find transformative applications in maritime environments, where similar demands for lightweight, high- strength, and environmentally responsible materials exist.

Frequently Asked Questions

What makes LMPAEK™ hydrofoils recyclable? LMPAEK™ hydrofoils are recyclable because they’re made from thermoplastic polymers that can be repeatedly melted and reformed without losing their mechanical properties, unlike traditional thermoset composites which undergo irreversible chemical changes during curing.

How do recyclable hydrofoils compare to traditional ones in performance? Recyclable LMPAEK™ hydrofoils match or exceed traditional thermoset performance in strength, stiffness, and fatigue resistance while offering superior chemical resistance and impact strength, plus the added benefit of complete recyclability.

What is the environmental impact of marine composites? Traditional marine composites create significant waste at end-of-life, contributing to approximately 1.5 million tonnes of composite waste annually in Europe. Recyclable composites can reduce this environmental burden by 80% through circular economy principles.

Ready to Explore Sustainable LMPAEK™ Solutions?

Learn More About LMPAEK™ Polymers

References and Further Reading

-

CompositesWorld: "Breton companies launch recyclable hydrofoil design project"

-

Victrex Blog: "Beyond Metals & Thermosets: Why Industry Leaders Are Switching to LMPAEK™ Polymers"

Stay Updated on LMPAEK™ Innovation

Follow us on LinkedIn Or Subscribe to our mailing list Photos Courtesy of Minilab