LMPAEK Properties Overview

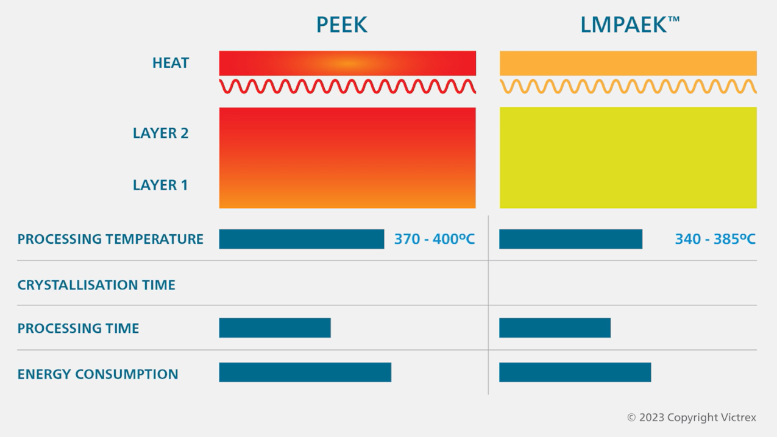

LMPAEK™ Polymers, the newest addition to the renowned PAEK family engineered by Victrex. Crafted with precision at a molecular level, Victrex has tailored these polymers to offer enhanced processing capabilities, providing manufacturers with greater flexibility in processes like thermoplastic composites and additive manufacturing.

Retaining the impressive traits of PEEK, including exceptional mechanical strength, tribological performance, and resistance to high temperatures and chemicals, LMPAEK™ polymers also unlock the potential for faster manufacturing and fabrication of stronger parts using common manufacturing systems.

Temperature Resistance

Excellent high temperature performance:

- Melting Point (Tm) = 305ºC

- Glass Transition (Tg) = 153ºC (midpoint)

- V-0 Flammability rating

Chemical Resistance

Excellent resistance to a very wide range of chemicals over a range of temperatures, retaining high levels of mechanical strength and generally with little swelling or discolouration.

Mechanical Strength

Excellent strength, stiffness

Wear Resistance

Electrical Properties

Victrex materials are often used as an electrical insulator with outstanding thermal, environmental resistance and mechanical performance.

PFAS-Free

We do not intentionally add, use or generate PFAS during the manufacture of unfilled Victrex PEEK and PAEK polymers.

High Purity

Victrex materials are inherently pure with very small amounts of low molecular weight volatile organics, resulting in exceptionally low outgassing and extractables even in high vacuum environments.

Hydrolysis Resistant

Victrex high performance polymers are not attacked by prolonged exposure to water, sea water or steam which makes them an ideal choice for use in applications such as medical components, subsea equipment, and valve components.

Processability

Victrex materials are some of the highest performing materials melt processable using conventional thermoplastic processing equipment.

Recyclable

Due to its high molecular stability, LMPAEK polymers can be re-melted and reprocessed repeatedly with minimal change to its properties. This helps its environmental footprint and can ensure that waste material from manufacturing processes can be re-used economically.