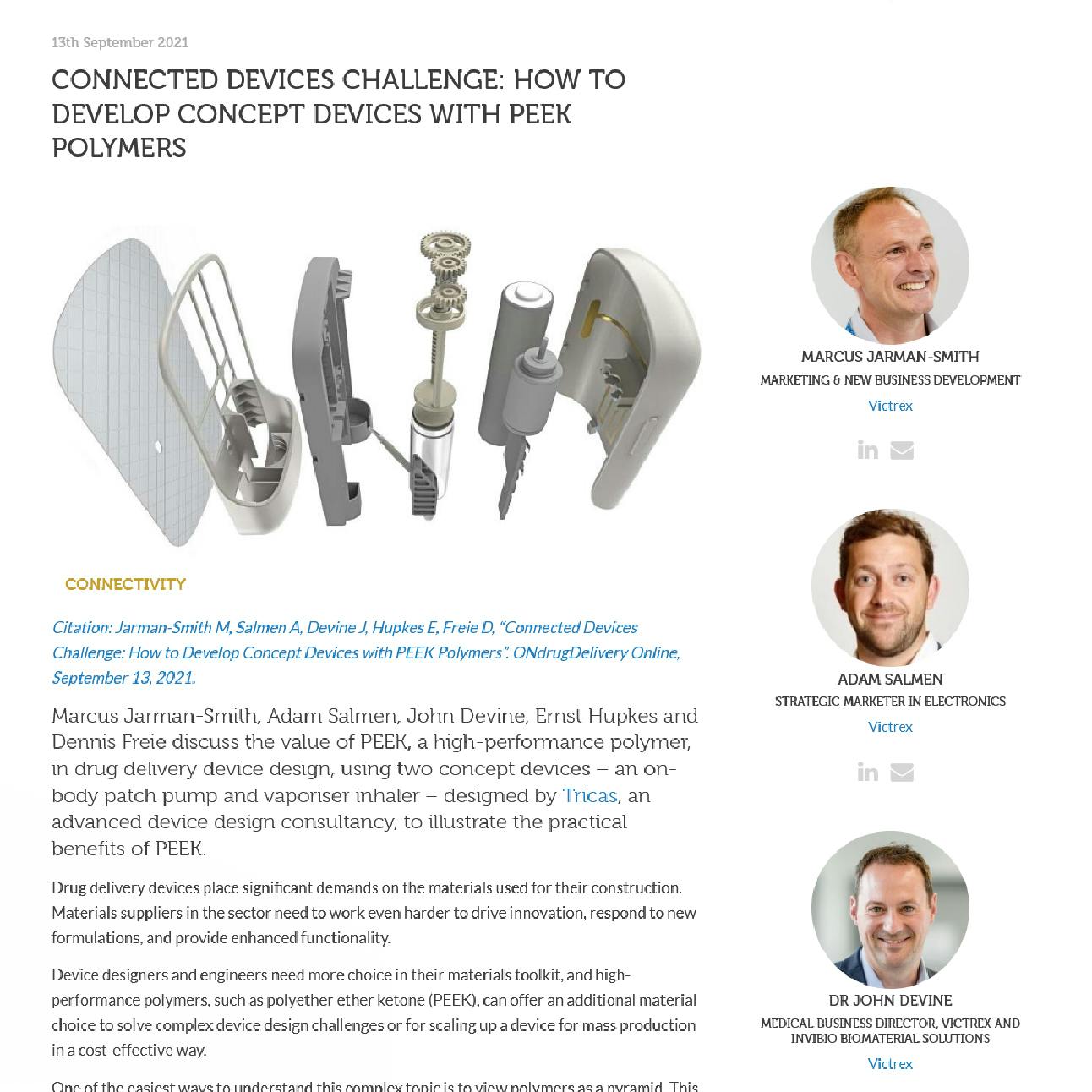

A multi-talent with proven performance

High temperature performance

Can be used near parts that generate heat over time

Longevity & performance over time

Lightweight and mechanical strength

Lightweight and durable to resist impact, and for continued use over time, even in miniaturised parts under load

Low moisture absorption

Low moisture absorption (0.05wt%) means components retain dimensions in biological environments, or when in contact with chemical or drug concentrates

High electrical integrity

Electrical insulative properties enable outstanding thermal, environmental resistance and mechanical performance for connected devices