The benefits of using VICTREX PEEK polymer for 3D printing

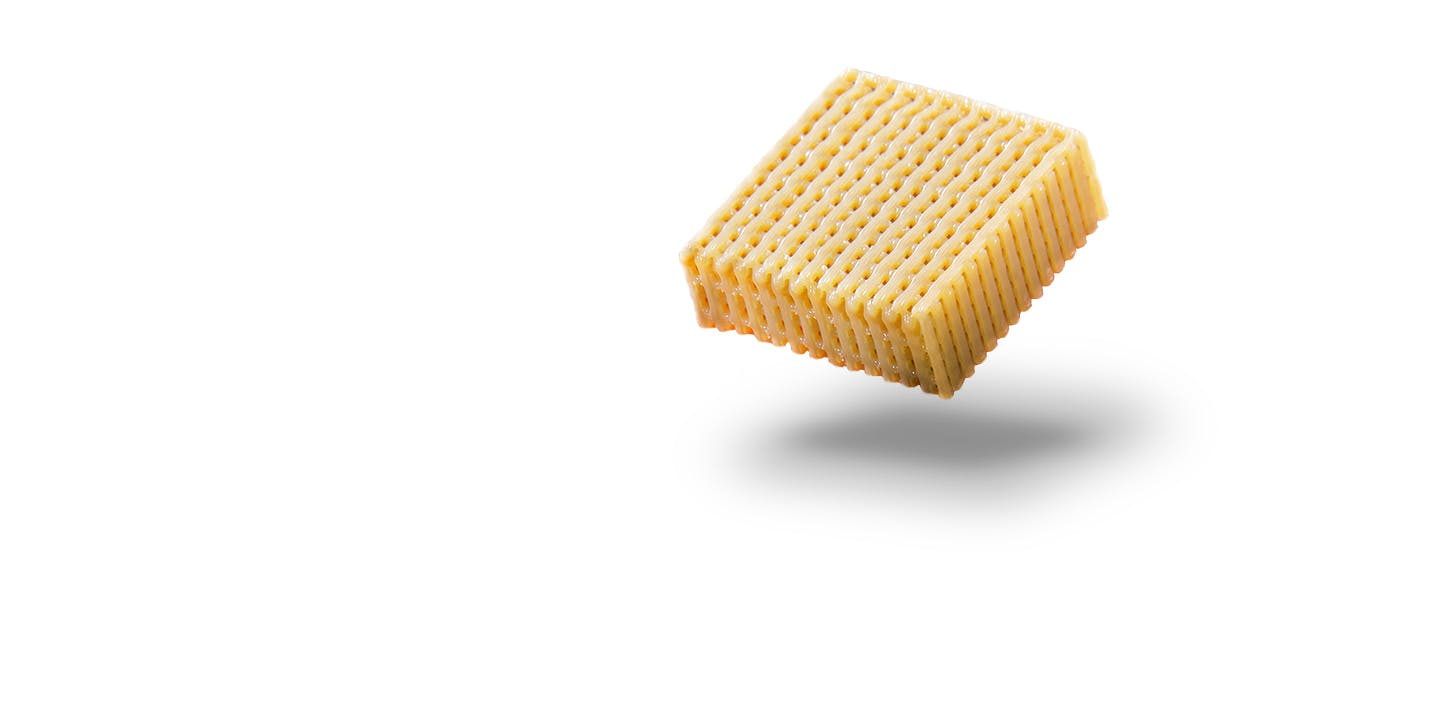

Greater design freedom

enabling the production of highly complex, customised components

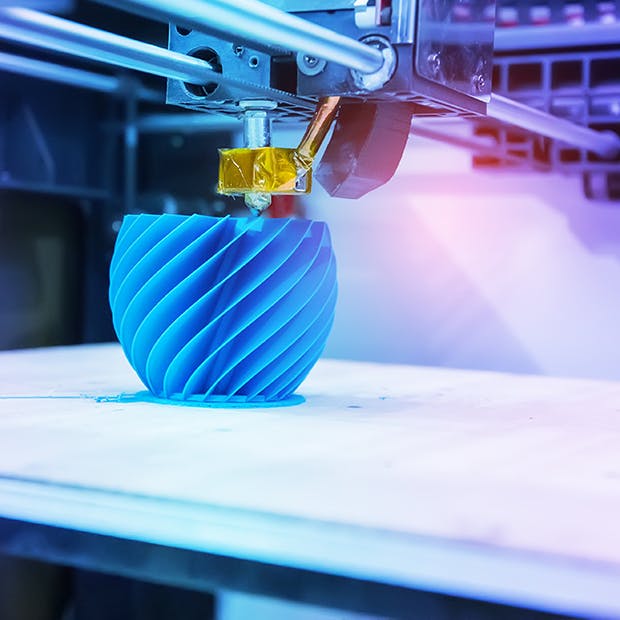

Accelerated speed to market

with digital design and fabrication of PAEK parts for rapid prototyping.

Improved economics

from reduced machining waste, assembly steps, and capital intensity.

High performance

All the benefits high-performance PAEK polymer combined with the benefits of additive manufacturing.

Stronger parts

New AM optimised materials and advancing machine technology both contribute to stronger parts.

Improved printing

with polymers offering less warp in filament fusion than traditional PEEK polymers.