VICTREX FG™

food and water-contact polymers

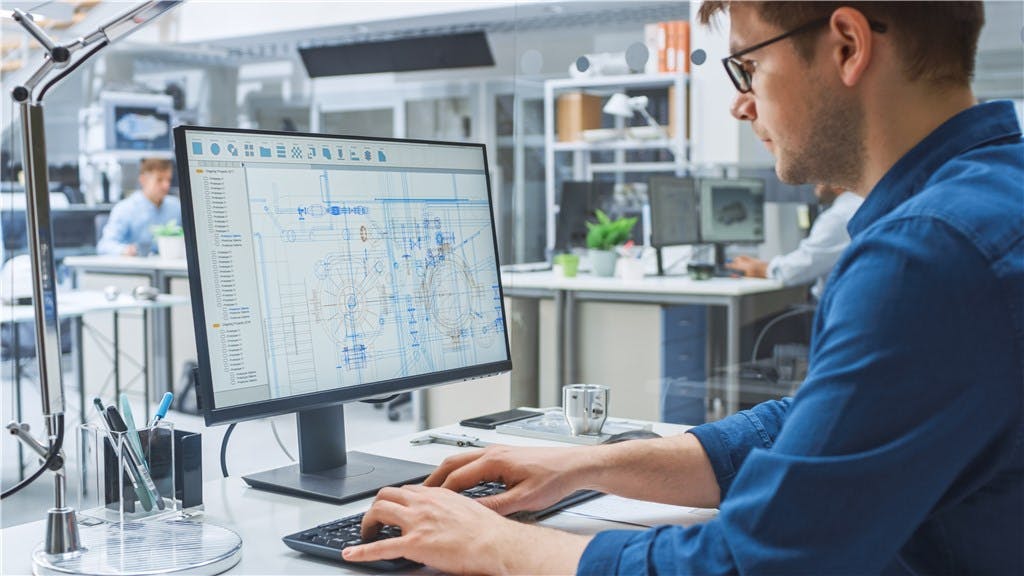

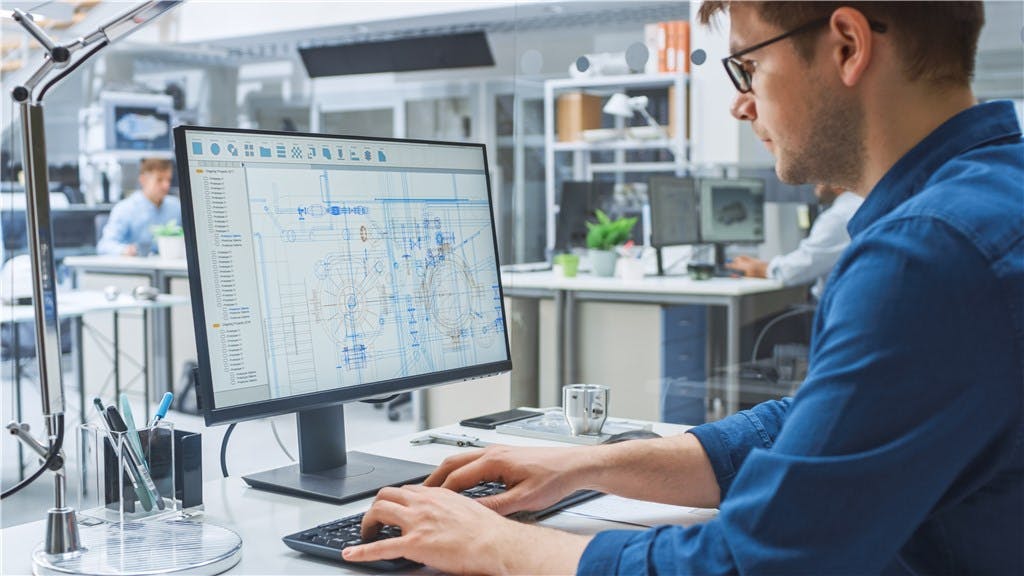

Challenges for food manufacturers

Challenges for food manufacturers

Industrial food manufacturing must meet the regulatory for foods such as meat, poultry, fish and dairy, and potable water. Combined with demands for improved taste experiences, longer shelf life, clean labels and product differentiation, VICTREX FG™ has been developed to enable innovation in extremely aggressive environments including: Conveyor systems, aseptic processing and packaging; and bottling and filling lines.

Reduce component costs by replacing metal components with the mass production of complex, resilient, injection moulded VICTREX PEEK components that require no further processing or machining. Typical applications include ovens, cookware, fryers and rice cookers. Additionally, beverage dispensers and coffee machine components such as piercing needles.

High-precision injection moulded parts and excellent material properties, deliver fabrication and end-use efficiencies in laboratory analytical equipment. VICTREX FG™ enables high-precision volume metering with minimum pressure loss; and precision moulding and durability in applications such as ultra-high pressure liquid chromatography.

Victrex keeps industrial environments moving, with high-performance polymer solutions to the highest safety standards. Our high-performance polymers power the pumps, valves and gears that you need to power industry 4.0.

VICTREX™ PEEK & thermoplastic hybrid gears offer an alternative to metal planetary system gearboxes. The high precision, tight tolerance and repeatability creates unconstrained cobot engineering design freedom.

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?