Downstream solution for future performance

APTIV™ FILMS

APTIV film provides unmatched durability and reliability in the most demanding application environments. It incorporates all of the outstanding properties of VICTREX™ PEEK polymer in a thin-film format. Its balance of properties makes it the highest performing, most versatile thermoplastic film available on the market.

Composite Tapes

Victrex are employing innovative PAEK-based composites to accelerate and expand markets within focus industries, working with customers to define solutions to address specific and unmet needs. Our composite solutions offer good performance in mechanically demanding applications, as well as lower weight, reliability, durability and reduced manufacturing costs.

VICTREX Pipes™ Solutions

From the ocean floor to outer space—long-term reliability of thermoplastic pipes in demanding operating conditions is the key to sustainable success. With all of the benefits of VICTREX™ PEEK polymer in a pipe and tube format, VICTREX Pipes are a proven alternative to metal that can help enhance system performance.

ZYEX™ Fibres

Across multiple industries there’s an increasing need for fibre solutions that can resist abrasion and chemical attack, at elevated temperatures. ZYEX™ Fibres can be used in diverse applications, from monofilaments for braided electrical cable protection to noise suppression fabrics for jet engines, to sports racket strings.

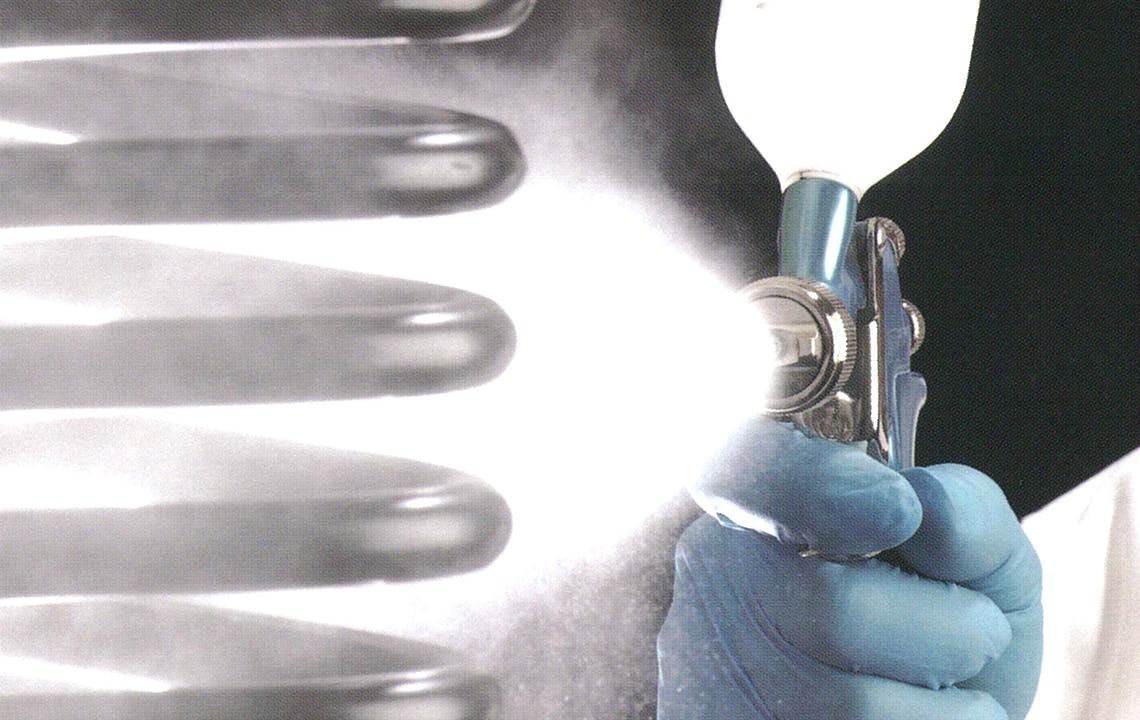

VICOTE™ COATINGS

VICOTE™ Coatings improve the wear performance and life of the coated part. Available in powder or aqueous dispersions, our VICTREX™ PEEK-based thermoplastic coatings can be easily applied to different part geometries, delivering excellent performance across a broad range of temperatures.

VICTREX AM™ 200 PAEK filament

VICTREX AM™ 200 PAEK filament has been specifically developed by Victrex for use in additive manufacturing with the approach to redesign the polymer at the molecular level, achieving better prints without using additives or plasticisers. The new material is designed to improve the 3D printing results of PAEK for stronger, more stable parts compared to PEEK.