Collaboration to drive future performance

Unlocking the possibilities for 3D printing PEEK and PAEK

Working together to achieve maximum

potential through the power of materials

Collaboration to drive future performance

Unlocking the possibilities for 3D printing PEEK and PAEK

Industry 4.0 with advanced technologies such as IoT and AI are becoming the norm for manufacturing worldwide and providing competitive advantages.

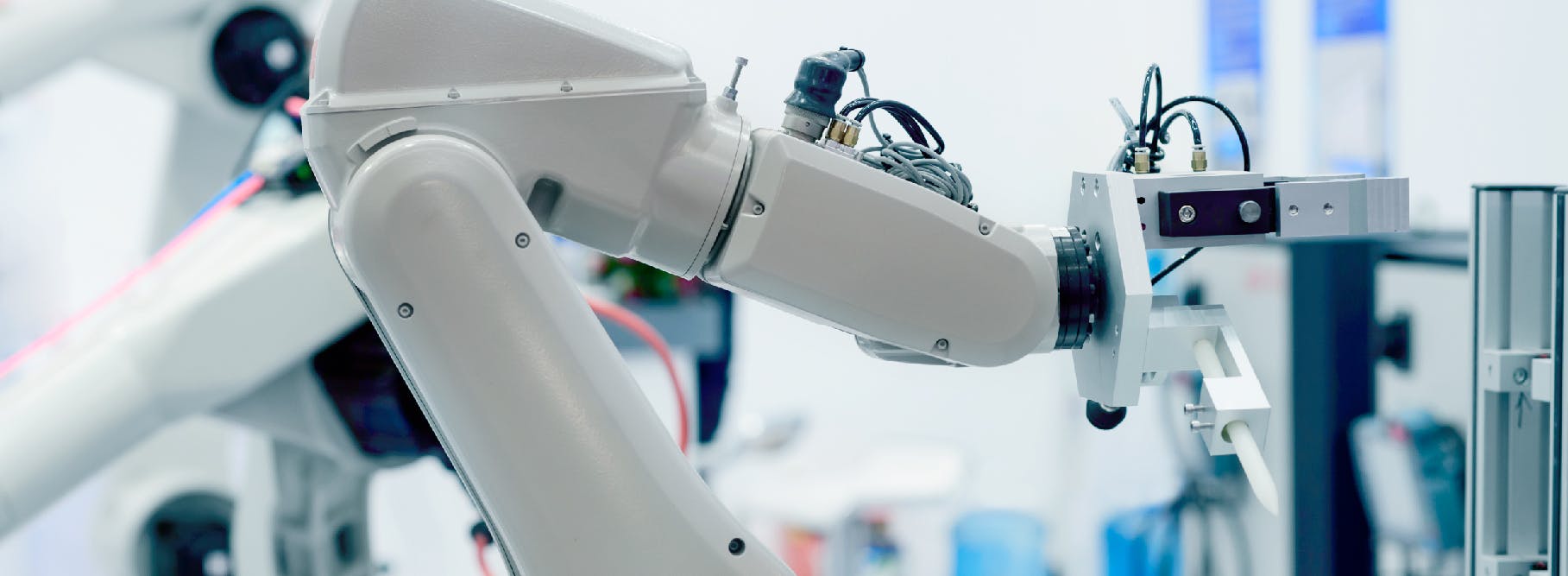

Collaborative robots have been steadily increasing in their contribution to manufacturing, working alongside humans to improve productivity and accuracy

Demand for food production is expected rise by 70% by 2050, and along with that there are increasingly complex and stringent regulations to ensure food and water safety

VICTREX FG™ polymer series are compliant with major food and water contact regulations and standards. Safe in the knowledge that these materials comply with applicable regulatory requirements, product managers, designers, engineers and project managers can use the series to facilitate their design choices

At Victrex, we work together with our manufacturing and equipment OEMs customers to help develop metal replacement solutions that address the demands of today and megatrends affecting tomorrow.

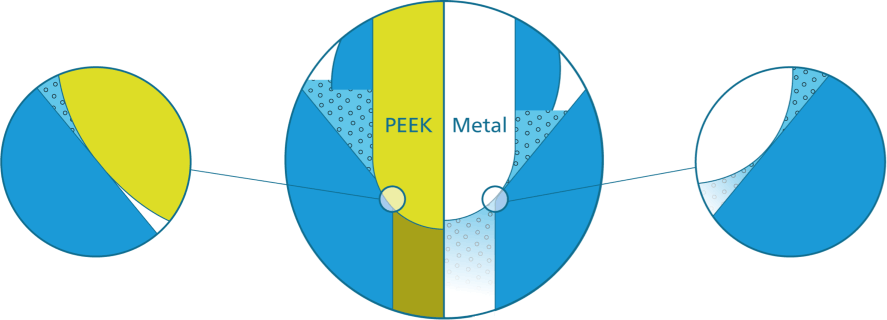

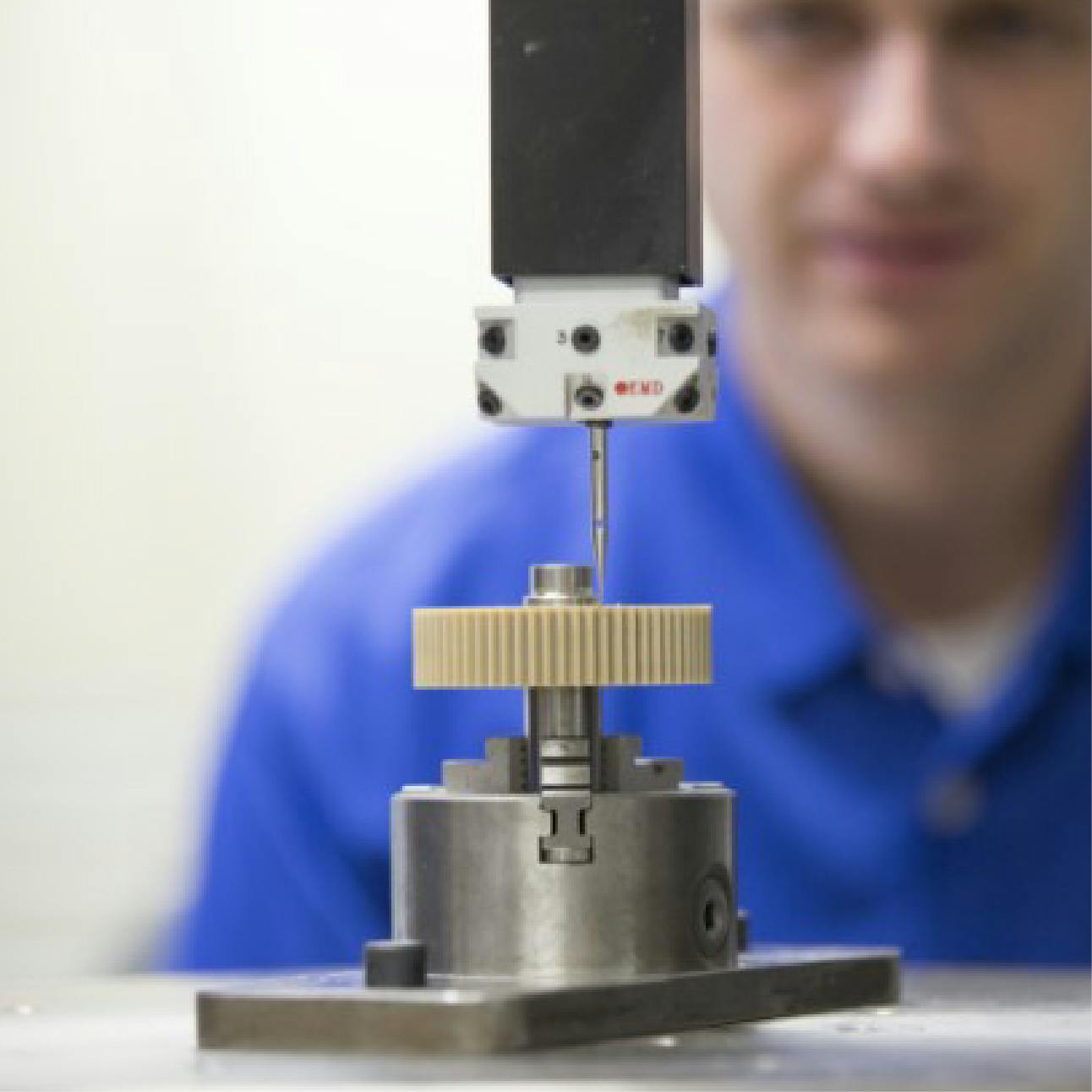

VICTREX™ PEEK & thermoplastic hybrid gears offer an alternative to metal planetary system gearboxes. The high precision, tight tolerance and repeatability creates unconstrained cobot engineering design freedom.

Victrex focuses on PEEK & PAEK polymers, considered the world's highest performing thermoplastics

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?