PEEK is Victrex. Victrex is PEEK.

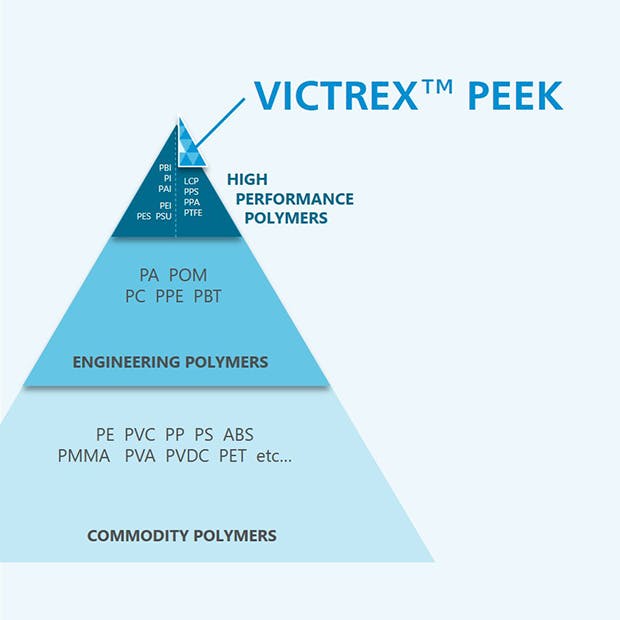

Victrex focuses on PEEK & PAEK polymers, considered the world's highest performing thermoplastics

Manufacturing product forms: Pipes, Films, Fibres and Composite tapes

Developing new applications for PEEK, PAEK and Thermoplastic Composites