VICTREX PEEK SOLUTIONS FOR THE NEXT GENERATION ELECTRIC VEHICLES

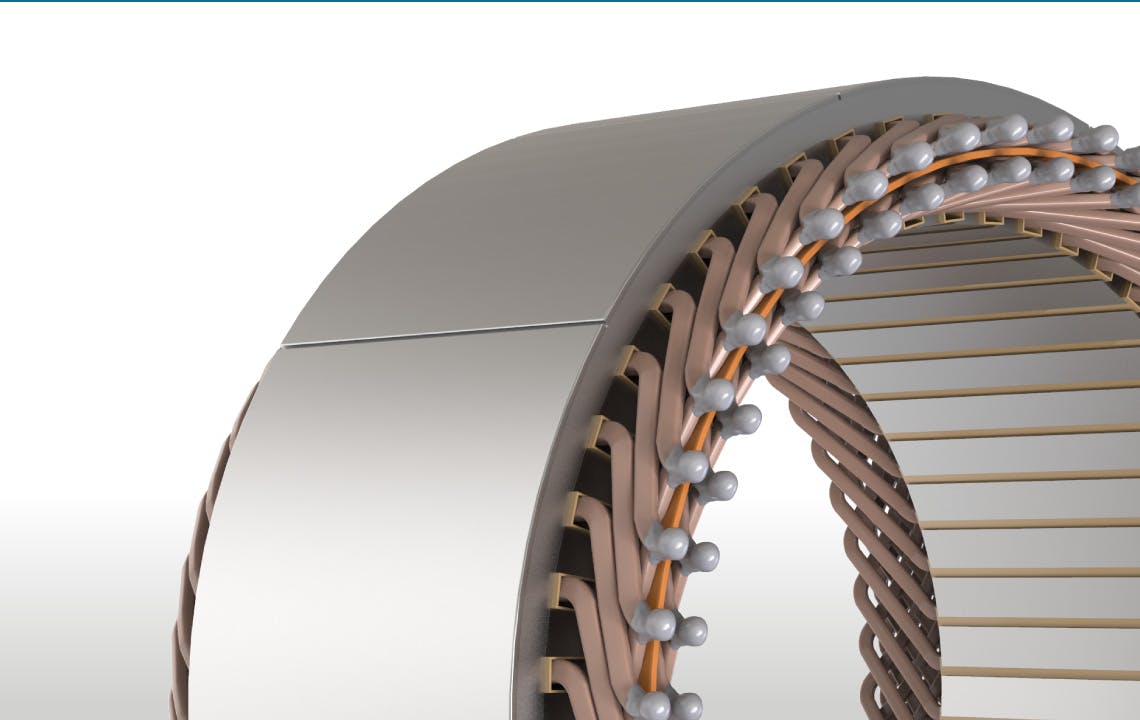

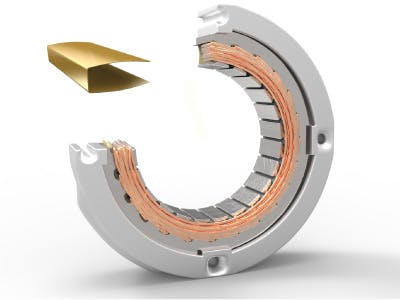

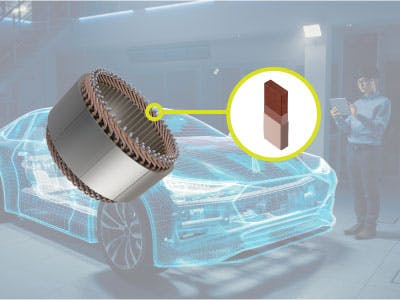

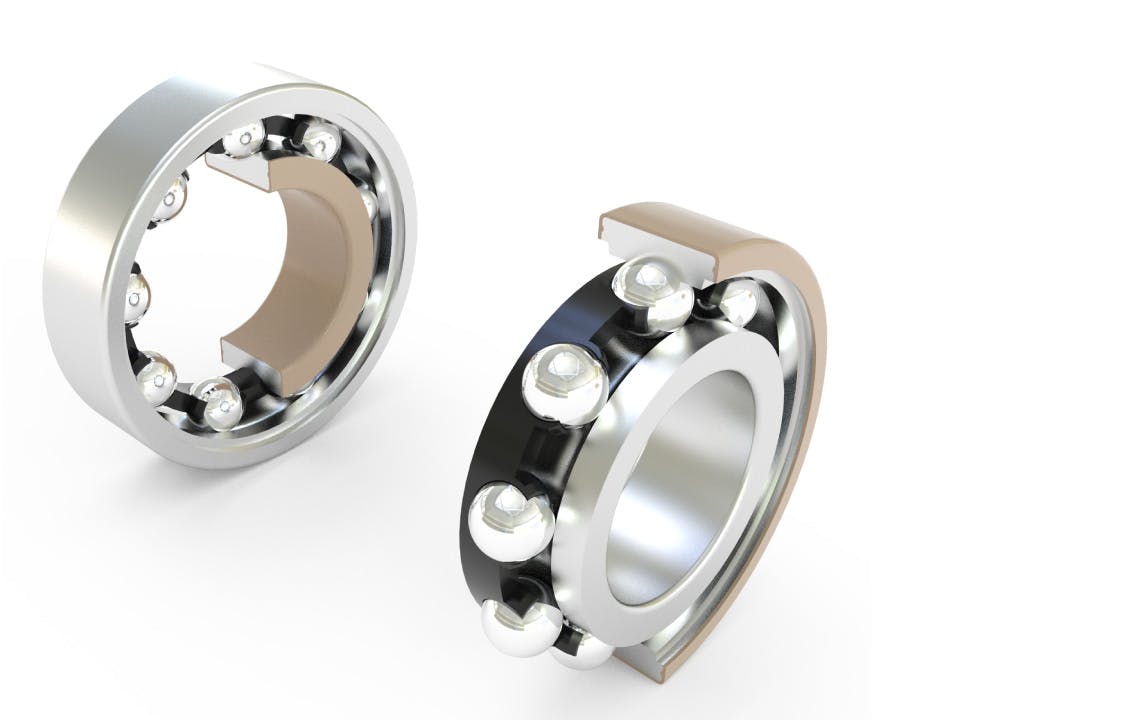

Future mobility requires new approaches in design and sustainable material selection, driven by the need to increase vehicle range, reduce cost, enhance driving and charging experience – all with without compromising on reliability and safety.

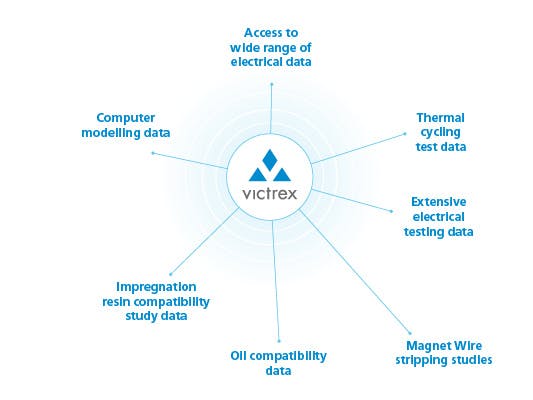

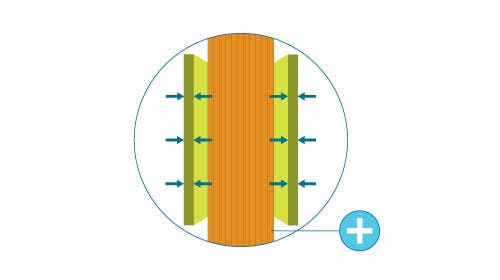

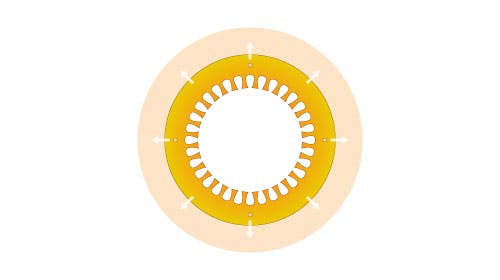

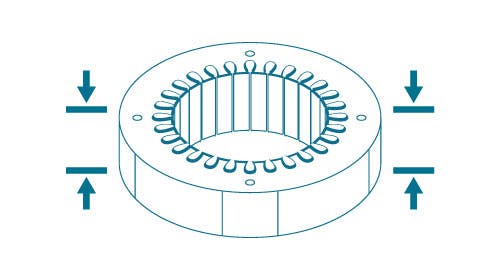

Explore how VICTREX™ PEEK based e-motor solutions can outperform traditional materials in 800V motors and support your sustainability goals, and why collaborating with our dedicated e-mobility team can help accelerate your e-motor projects.