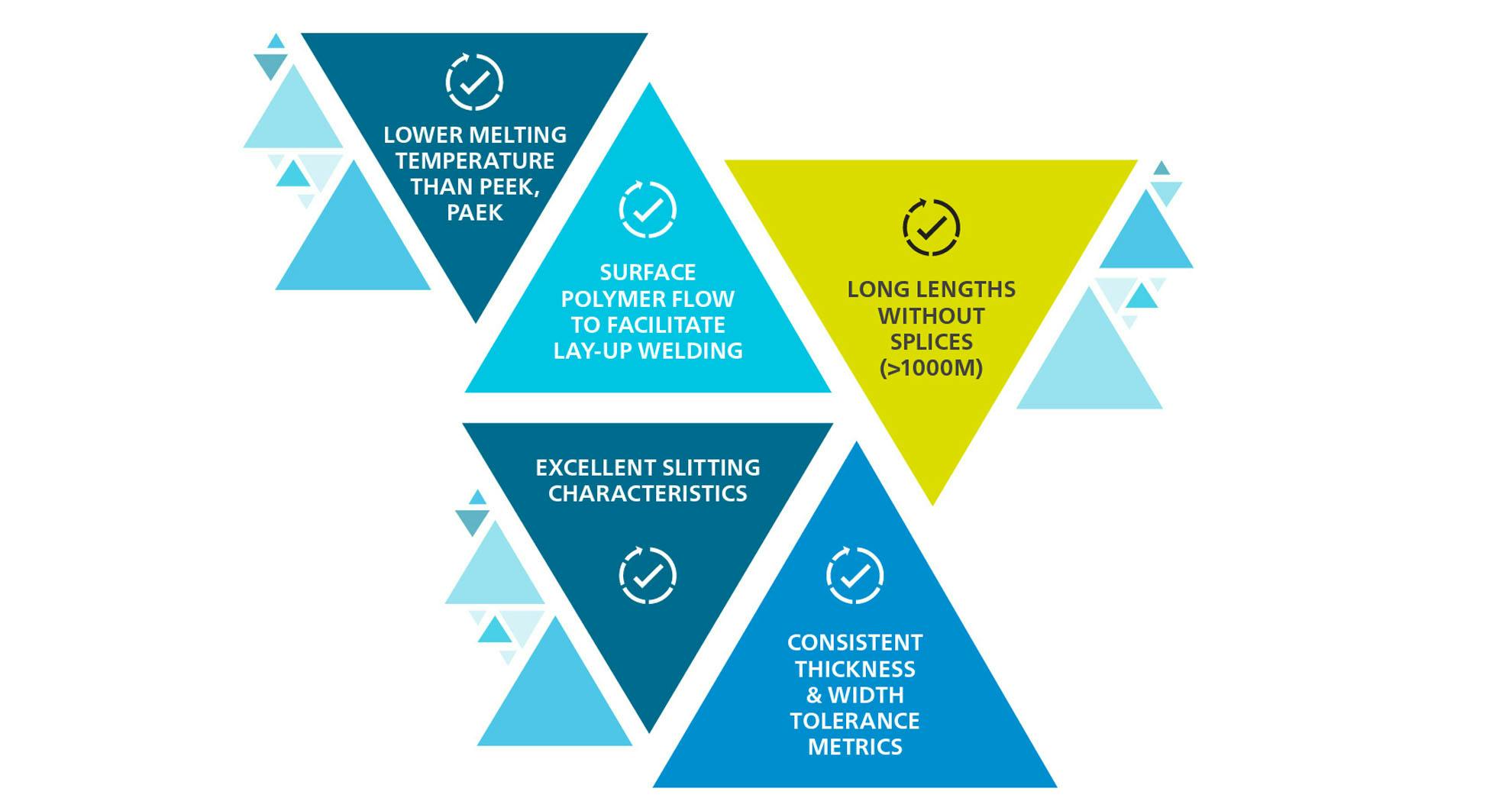

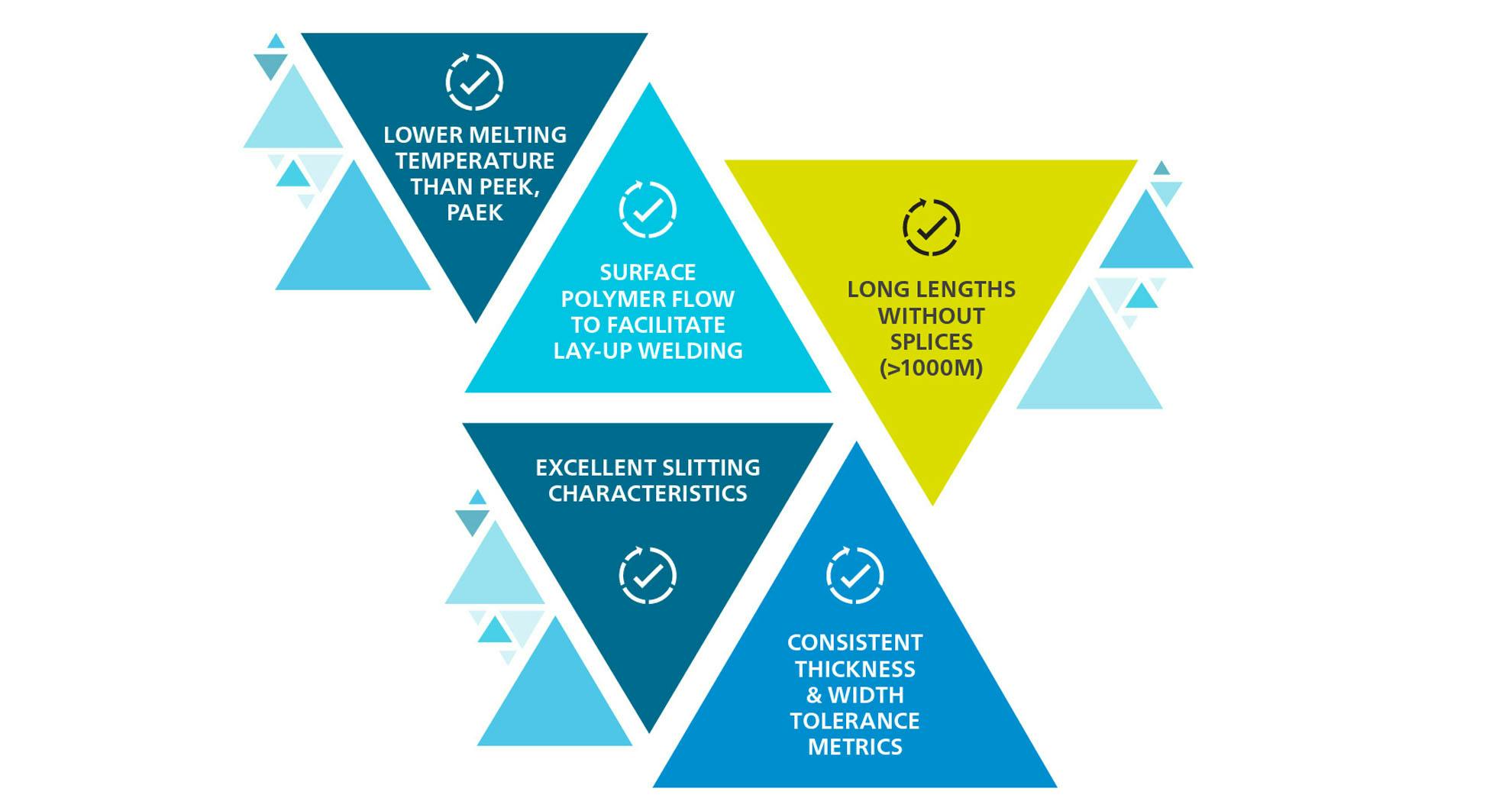

VICTREX LMPAEK KEY CHARACTERISTICS

High strength, low weight material with higher damage tolerance vs. thermosets.

Faster lay-down and energy savings achieved with automated production methods.

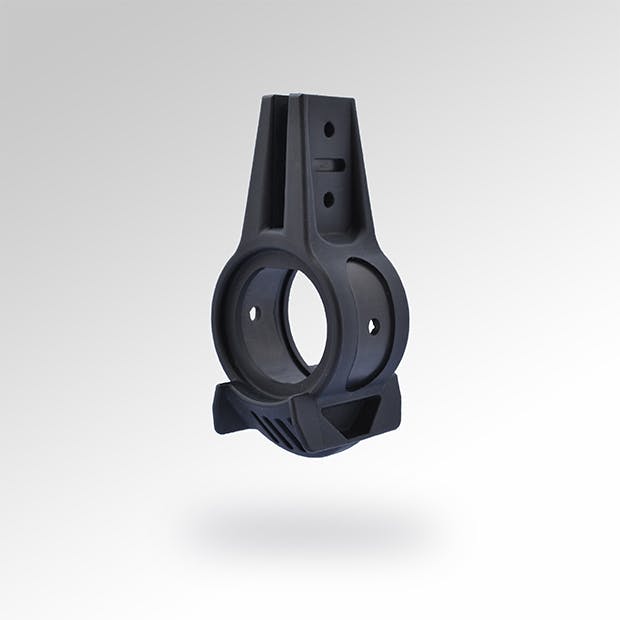

Well suited for a variety of applications and automated manufacturing techniques.

VICTREX LMPAEK UDT is a disruptive material, with the potential to reduce scrap rates, cycle times, part count, and buy-to-fly ratios. With our know-how in the processing and performance of PAEK materials, together we can optimise the design of your next composite component and commercialise your projects faster.

Contact us to start the design of your next composite project with VICTREX LMPAEK UDT.

Hi, do you have PEEK questions I can help with?