The next dimension of thermoplastic composites

Visit booth C07 to talk to a PEEK expert about your application challenges.

The Next Dimension of Thermoplastic Composites

Visit booth C07 to talk to a PEEK expert about your application challenges.

System cost reductions can be realized by reducing manufacturing time and scrap, eliminating secondary processes, and designing integral functionality into the part.

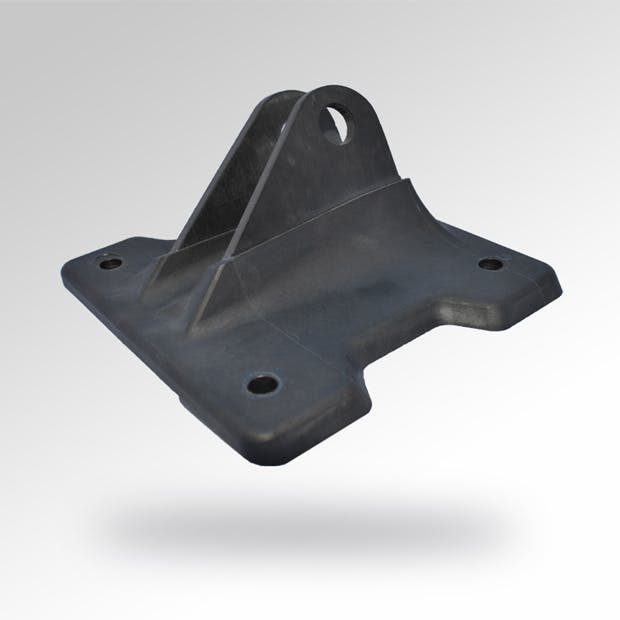

Combining the mechanical performance of fibre-reinforced composites with the design freedom of injection molding polymers allows for the design of complex parts, with good mechanical performance previously not thought possible.

Hybrid solutions can deliver weight savings up to 60% compared to metal alternatives. Tailored designs offer equivalent or better mechanical properties such as strength, stiffness, and fatigue.

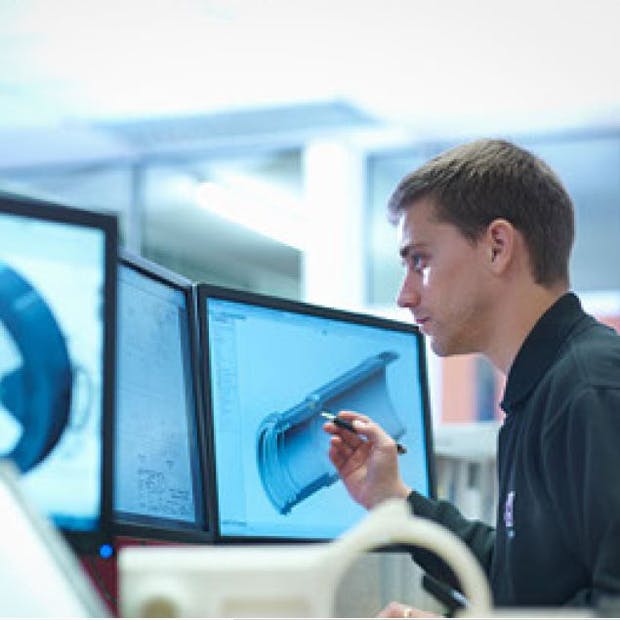

The design freedom made possible through innovative materials and manufactures enables engineers to think differently about design. Expanding the design window to parts integration can lead to reduced part count.

Combining advanced process control techniques and state-of-the-art automation to achieve unrivaled production speeds without sacrificing quality.

Delivering repeatable high-quality custom PAEK laminate and preformed inserts manufactured to your specification.

“The original idea was to create a sort of center of excellence where you could do all of the design and engineering, get tools built, make prototypes and, ultimately, produce commercial parts.”

Jonathan Sourkes -

Victrex Head of Sales for Aerospace

Article from CompositesWorld Magazine

Hi, do you have PEEK questions I can help with?