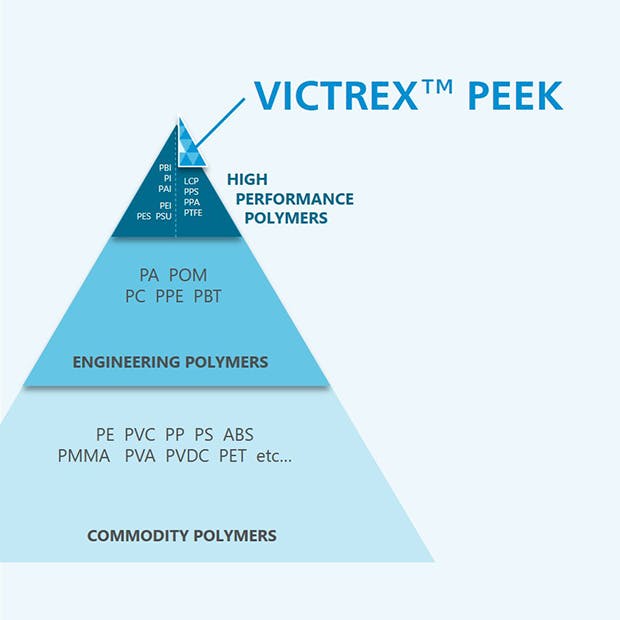

VICTREX™ PEEK polymer is regarded as one of the highest-performing engineering thermoplastics in the world.

It’s the specified powerhouse of performance, delivering multiple engineering requirements - from resistance to high temperature, harsh chemicals, wear, to mechanical strength, electrical properties, and more – all with one polymer. It has been helping engineers solve complex engineering challenges for more than 40 years – often resulting in replacing metal and other polymers.

VICTREX 450G™ PEEK, used by leading brands globally, is a standard flow general purpose PEEK grade for injection moulding and extrusion, which is natural/beige coloured.

Depending on your needs and application areas, there could be more suitable PEEK-based products, such as wear grades or food grades. Visit our Technical Datasheets section to learn more.

We work in alliance with our authorised distributors to deliver products made with VICTREX 450G around the globe

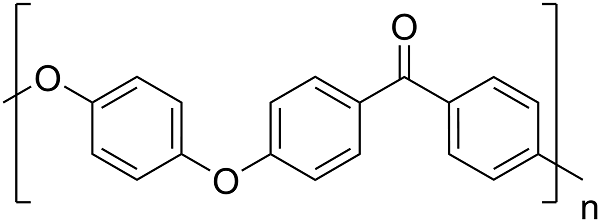

PEEK is a general term, an abbreviation, for the polayaryletherketone (PAEK) polymer [whose full name is poly(oxy-1,4-phenyleneoxy-1,4-phenylenecarbonyl-1,4-phenylene) ] and whose molecular backbone structure is defined by the repeat unit below.

VICTREX PEEK 450G is a specific grade of PEEK polymer, a unique grade which is only made by Victrex and which has a specific range of molecular weight. The molecular weight defines the bulk properties of the PEEK 450G polymer, including its stiffness, strength, toughness, crystallinity and melt processing behaviour.

VICTREX PEEK 450G is defined as a standard melt viscosity (MV) PEEK grade, with a medium molecular weight. Other VICTREX PEEK grades are available with higher and lower melt viscosities and higher or lower molecular weights respectively. VICTREX PEEK 150G is a higher flow, lower molecular weight, lower MV grade of PEEK compared to 450G. [A lower melt viscosity, measured in Pa.s, equates to a higher Melt Flow Rate (MFR)]. As a result, 150G may be more suitable for applications where lower viscosity in the melt during processing is desirable, for example, when injection moulding thin-walled parts or long, thin sections with intricate geometries; impregnating carbon or glass fibres for composite prepregs; or adding high levels of solid fibrous or particulate fillers and reinforcements to make compounds. However, the lower molecular weight also changes the bulk properties of the polymer: lower molecular weight PAEKs have higher stiffness and strength combined with reduced toughness, ductility and impact resistance. This is a consequence of the shorter polymer chains, which are less entangled, crystallise more readily and to a greater overall extent. Some of the properties of 450G and 150G are compared in the table below to illustrate these differences.

| Property | Units | Test Method | VICTREXTM PEEK 450GTM | VICTREXTM PEEK 150G |

|---|---|---|---|---|

| Typical values | ||||

| Melt viscosity, 400°C/1000s-1 | Pa.s | ISO 11443 | 350 | 130 |

| Melt flow rate, 380°C/5kg | g/10 min | ISO 1133 | 8.5 | 75 |

| Tensile modulus, 23°C | GPa | ISO 527 | 4.0 | 4.1 |

| Tensile strength, 23°C | MPa | ISO 527 | 98 | 105 |

| Tensile elongation at break, 23°C | % | ISO 527 | 45 | 30 |

| Flexural modulus, 23°C | GPa | ISO 178 | 3.8 | 3.9 |

| Flexural strength, 23°C | MPa | ISO 178 | 125 | 130 |

| Izod impact strength, notched, 23°C | kJ/m2 | ISO 180 | 8.0 | 5.0 |

| Melting point, Tm | °C | ISO 11357 | 339 | 342 |

| Crystallisation temperature, Tc | °C | ISO 11357 | 290 | 296 |

| Degree of crystallinity, typical | % | ISO 11357 | 35 | 39 |

We help customers deliver new solutions to shape the world we live in, transforming industries and people’s lives.

As the #1 PEEK experts we can advise customers on PEEK in ways no other company can, supporting organisations to accelerate their growth ahead of the market by delivering disruptive technologies.

We aim to help accelerate business success for all, in close collaboration with customers. We can support every stage of component development, from concept to commercialisation and help develop new supply chains to bring solutions to market.

Hi, do you have PEEK questions I can help with?