PEEK (Polyetheretherketone) 聚醚醚酮聚合物是什么?

什么是PEEK?

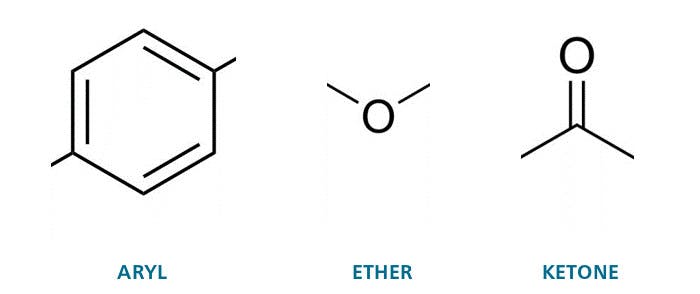

PEEK或聚醚醚酮属于“芳香族聚酮”(更准确地说是聚芳醚酮或PAEK)类聚合物,由以下结构单元构成:

对PAEK的研发起源于20世纪60年代,但直到1978年帝国化学工业公司(ICI)才对PEEK申请了专利,而威格斯PEEK聚合物于1981年首次实现商业化。

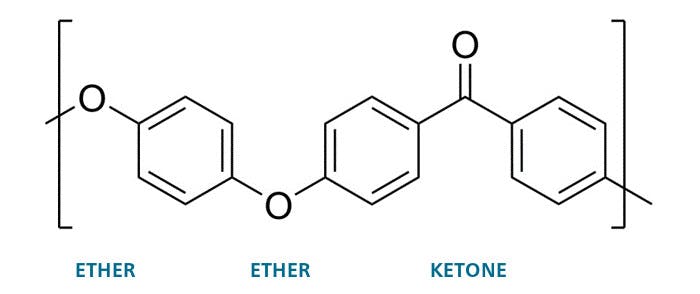

“芳香族”通常意味着独特或香甜的味道,这看似一个奇怪的词语,但科学家们用它来描述某些包含有或由环状结构构成的分子(如上面的芳基结构单元)。此类型小分子,如甲苯和萘,具有独特的气味并因此而得名。但PEEK本身就像大多数热塑性塑料一样,在正常情况下是无味的。从化学角度来看,PEEK主要是一种线性半结晶聚合物。下图阐释了结构单元如何相互结合,从而形成醚醚酮或EEK:

上面方括号中所示的“重复单元”被复制很多次——平均在200-300次之间——从而形成一个PEEK聚合物链。P来自于希腊语“poly”是“很多”的意思,这样很多EEK就形成了PEEK。芳基和酮基具有一定刚性,因而提供了刚度,这意味着良好的机械性能和高熔点。醚基提供了一定程度的柔韧性,而芳基和酮基具有化学惰性,从而具有耐化学腐蚀性。重复单元的规整结构意味着PEEK分子可部分结晶,而结晶性可提供耐磨、抗蠕变、抗疲劳和耐化学性等性能——稍后将对此进行详细介绍。

形成的聚合物被广泛公认为是世界上性能最好的热塑性塑料之一。与金属相比,PEEK类材料重量轻、易成形、耐腐蚀,并具相当高的比强度(单位重量强度)。

根据应用需要进行设计

我们采用了可控制链长或分子量的工艺来制造PEEK。与短链PEEK相比,长链PEEK(高分子量)具有更强的韧性和抗冲击性。但高分子量聚合物在熔融时非常粘稠,这限制了将其注入小型模具的能力。低分子量PEEK的抗冲击性能较差,但在熔融状态时流动性更好,因此易于制造复杂的小零件。

准备好找到符合您应用需求的 PEEK 等级了吗?

PEEK 有多个等级可供选择——每种等级都针对不同的分子量、增强水平和加工要求进行了优化,因此找到正确的规格对于实现最佳性能至关重要。

| 性能 | 数值 | 测试方法 |

|---|---|---|

| 熔点(Tm)(1) | 343°C (649°F) | ISO 11357-3 |

| 玻璃化转变温度 (Tg)(1) | 143°C (289°F) | ISO 11357-2 |

| 热变形温度(1) | 152°C (306°F) | ISO 75-2/Af |

| 导热系数(1) | 0.29 W/m/K | ISO 22007-4 |

| 热膨胀系数 (低于Tg, 平均值)(1) | 55 ppm/°K | ISO 11359-2 |

| 热膨胀系数 (高于Tg, 平均值)(1) | 140 ppm/°K | ISO 11359-2 |

PEEK 的热性能

数据来源 1 VICTREXTM PEEK POLYMER 450TM

热性能: 260℃ 连续使用温度

测试表明 VICTREX PEEK 聚合物 的连续使用温度可达260°C (500°F). 这使其适用于各种高温环境,如流程工业、油气行业以及数百万辆汽车的发动机和变速器内部。 PEEK能够在动态应用中承受摩擦并抵抗磨损,例如止推垫圈和密封环等。

化学耐受性: 在苛刻环境中的表现

| 化学类别 | 耐受性 |

|---|---|

| 碳氢化合物 (脂肪族、芳香族)(1) | 优异 |

| 有机溶剂(醇类、醛类、酮类、醚类)(1) | 优异 |

| 酸(盐酸、磷酸)(1) | 优异 |

| 强碱 (NaOH, KOH)(1) | 优异 |

PEEK的化学性能

数据来源 1 VICTREX PEEK Chemical Resistance Brochure

PEEK能够抵抗在化学腐蚀性操作环境中可能造成的伤害,例如油气行业井下环境,以及机械和汽车应用中的齿轮。它可以耐受航空航天行业使用的喷气燃料、液压油、防冰剂和杀虫剂。这种性能在广泛的压力、温度和时间范围内依然保持稳定。

机械强度:跨温度范围的承载性能:

| 性能 | 数值 | 测试方法 |

|---|---|---|

| 拉伸强度 (23°C)(1) | 78 - 330 MPa | ISO 527 |

| 弯曲强度 (23°C)(1) | 125 - 480 MPa |

ISO 178 |

| 弯曲模量 (23°C)(2) | 3.2 - 37 GPa | ISO 178 |

| 压缩强度 (23°C)(1) | 105 - 310 MPa | ISO 604 |

| 缺口冲击强度 (Notched, 23°C)(1) | 3.5 - 11 kJ/m² | IISO 180/A |

PEEK的机械性能

数据来源 1 Victrex PEEK Properties Guide

蠕变和疲劳抗性:长期耐久性

PEEK在宽广的温度范围内表现出卓越的强度和刚性。以PEEK为基础的碳纤维符合材料,其比强度远高于金属和合金。“蠕变”指的是材料在持续受力的情况下,经过长时间后发生永久变形;“疲劳”则是值材料在反复循环载荷作用下发生脆性断裂。由于其半结晶结构,PEEK同时具有很高的蠕变和疲劳抗性,并且已被证明在长久的使用寿命中,比许多其他聚合物甚至部分金属更耐用。

阻燃性能:火灾、烟雾毒性

PEEK具有卓越的阻燃性能。它能够抵抗接近600℃的自燃温度。当在极高温度下被迫燃烧时,它不会维持燃烧,并且仅释放极少量延误。这也是PEEK被广泛应用于商业飞机的原因之一。

加工多样性:从挤出到注塑成型

PEEK分子结构非常稳定,因此聚合物可以反复熔融并重新加工,而其性能几乎不会发生变化。这不仅有助于降低环境影响,还能确保制造过程中产生的废料可以通过机械方式回收再利用。

作为一种热塑性材料,PEEK可以使用常规的热塑性加工设备进行注塑、压塑成型以及挤出加工。它具有极高的加工灵活性,并且越来越多地用于提升零部件性能、耐久性、减轻重量以及降低整体生命周期系统成本。难怪它正在取代金属和合金!

在众多行业和关键应用环境中,材料专家、零部件设计师和采购人员必须决定:是选择PEEK作为材料,以实现性能提升、减重、降低能耗、缩短装配时间、节约成本,还是继续坚持使用传统的金属和合金。

PEEK 与其他高性能聚合物的性能比较

与其他高耐热聚合物,如PPS (聚苯硫醚)和PES (聚醚砜)相比,PEEK因其在耐热性、耐磨性、耐化学性以及机械性能方面的卓越平衡而脱颖而出。根据UL746B标准,PEEK的连续使用温度(相对热指数)可高达260℃,明显高于PPS (约240℃)和PES(约180℃),使其非常适用于需要在极端温度下保持性能的应用。相比于在较低温度下可能软化的PPS,PEEK即使在高热应力下仍能保持机械完整性。 在机械强度方面,PEEK的拉伸强度显著高于PPS和PES。虽然PPS以其耐化学性和加工便利性而闻名,但它缺乏PEEK的韧性和强度,而这些特性在需要耐久和承载能力的应用中至关重要。PEEK出色的耐磨性能和低摩擦系数也使其在高应力环境中比PES更具优势,因为PES在此类条件下通常表现出较差和耐磨性能。

PEEK: 赋能未来工程挑战

PEEK不仅仅是一种高性能聚合物——它是一种不断推动工程可能性边界的材料。其多功能性、强度和韧性使其在解决众多行业最严峻挑战中发挥着关键作用。因此,PEEK不仅关乎今天的应用,更关乎未来。随着技术的发展和需求的日益严苛,它将带来更多可能性。 如果您正在寻找一种具备卓越耐久性、耐高温性和化学稳定性的材料,PEEK或许就是您一直在寻找的答案。 想了解PEEK如何为您的特定项目或应用带来优势,欢迎联系我们了解更多信息。

PEEK常见问题解答

PEEK (poly-ether-ether-ketone) 应用在哪些领域?

PEEK在金属和标准聚合物无法满足多项关键工程要求的关键应用中发挥着重要作用。主要包括:

- 航空航天:发动机部件、结构件、电缆绝缘——需要强度、耐磨性,符合烟雾、火灾、毒性质量标准,并实现减重。

- 汽车:传动部件、止推垫圈、密封环——要求可靠性、耐磨性能、高温下的性能以及耐化学性。.

- 油气行业:井下部件、密封件、轴承——需要耐化学腐蚀、在压力下的性能、极端温度下的表现以及可靠性。

- 医疗:手术器械、植入式装置、灭菌托盘——要求生物相容性、可反复高压蒸汽灭菌、机械性能稳定。

- 工业:化学加工设备、半导体部件、电气连接器——利用其化学惰性和尺寸稳定性。

PEEK 与金属相比如何?

PEEK在苛刻应用中相比金属具有多项优势:

性能优势:

- 连续使用温度可达260℃,与许多金属应用相当。

- 比强度(单位重量的强度) 通常超过金属

- 完全化学惰性(无腐蚀,相比金属氧化/降解)

- 在动态应用中具备卓越的耐磨性能

- 电绝缘性能(相比金属的导电性)(注意:填充碳纤维的PAEK——包括化合物和复合材料——具有导电性,而VICTREX ESD 101则是部分导电的。

实用优势:

- 相比金属部件减重40-50%

- 通过注塑成型实现复杂几何结构(避免机械加工的限制)

- 降低装配成本(卡扣连接、焊接接头替代紧固件)

- 减少维护需求(无需防腐蚀保护)

权衡因素:

- 材料单价更高 (但可通过减重和生命周期节省来抵消)

- 绝对强度低于部分金属 (但比强度更高)

- 加工温度要求较高 (360-400℃,相比金属成型)

PEEK能耐受多少温度?

PEEK展现出卓越的热性能:

- 连续使用温度:260°C (500°F) - 根据UL746B 测量验证,并已在汽车和航空航天应用中累计数百万小时使用

- 熔点:343°C (649°F) - 在远高于工作温度的条件下仍保持固态结构

- 玻璃化转变温度:143°C (289°F) - 在此转变温度以上仍能保持机械性能

- 短期高温耐受性:可在300°C以上短暂暴露而不发生永久性降解

这种热性能显著优于其他高性能聚合物:

- PPS: 连续使用温度240°C (比PEEK低20°C)

- PES: 连续使用温度180°C (比PEEK低80°C)

PEEK是否优于PPS?

PEEK 和 PPS 满足不同的应用需求:

选择 PEEK 的情况:

- 需要连续运用温度超过240°C

- 动态应用中要求最高耐磨性能

- 对最高机械强度有关键要求

- 规格要求性能优势,能够证明高成本的合理性

选择 PPS 的情况:

- 工作温度低于240°C

- 成本敏感性较高

- 加工便利性优先 (PPS流动性更好)

性能对比:

- PEEK 的连续使用温度高出 20°C (260°C vs 240°C)

- PEEK 具备更优的耐磨性能和更高的拉伸强度

- PPS 成本约比PEEK低 30%

- PPS 加工更容易,周期更短

实际应用建议: 如果您的应用运行温度在 230-240°C之间,且接触腐蚀性化学品,或需要动态耐磨性能,PEEK的性能优势通常能通过延长部件寿命和减少维护来证明其成本合理性。 对于低于230℃且无极端耐磨要求的应用,PPS 通常能提供出色且经济高效的性能。

PEEK的成本是多少?

PEEK 原材料价格反映其高性能特性:

材料成本考虑:

- PEEK 的成本显著高于普通工程塑料,(如PPS、尼龙、聚甲醛)和替代金属材料(如铝,钢、钛)。

- 价格因等级而异:未、玻纤填充、碳纤填充等级成本不同。

设计效率与废料减少的优势:

- 从金属转向 PEEK 可重新设计部件,提高性能并减少材料使用。

- 从金属加工废料可达80%,注塑成型通常废料低于5-10%。

- PEEK 按重量销售,但在注塑应用中按体积使用。

- 其低密度(约为铝的一半,钢的六分之一)意味着同样部件所需材料更少

想知道高性能聚合物与金属的对比吗? 请阅读我们的博客: PEEK vs 金属:高性能聚合物如何超越金属

生命周期成本优势:

- 相比金属减重40-50%,降低材料使用量

- 通过复杂成型实现部件整合,减少装配成本

- 延长使用寿命 (比其他聚合物长2-4倍),降低更换频率。

- 降低维护中(无腐蚀,耐磨性优异),降低总拥有成本

- 在关键应用中减少停机时间,节省运营成本

成本合理性框架:M材料研究人员和采购团队通常通过一下方式接受 PEEK 的溢价:

- 应用关键性 (故障成本远超材料成本溢价)

- 生命周期分析 (通过延长寿命实现2-3年回报)

- 性能要求(无其他聚合物可满足规格)

- 系统级节省(减重、部件整合、简化装配)

关于作者

John Grasmeder 拥有超过 30 年的全球聚合物领域经验,曾在 ICI、BASF 以及多家英国和德国的 BASF、Hoechst 和 Shell 合资企业担任研发、应用开发、市场营销和业务领导职务。

在现任职位中,John 正致力于在不断扩展的可持续技术平台、产品、工艺和应用领域,构建威格斯的研究基础。

John是埃克塞特大学的名誉教授,材料化学知识中心行业指导委员会(Knowledge Centre for Materials Chemistry’s)主席及其管理委员会成员。同时,他还是 热塑性复合材料研究中心联盟(Thermoplastics Composites Research Centre)董事会成员、未来生物制造研究中心(Future Biomanufacturing Research Hub)顾问委员会成员,以及 利物浦大学数字与自动化材料化学博士培训中心工业(Centre for Doctoral Training in Digital & Automated Materials Chemistry)顾问委员会成员,并参与 英国标准协会塑料测试委员会(British Standards Institution’s Committee for the Testing of Plastics)的工作。

John 获得了 南安普顿大学化学学士和博士学位,是注册工程师,英国皇家化学学会、材料矿物与采矿学会以及化学工程师学会的会士。他拥有 50 多项专利和出版物。