Power to progress polymer solutions

75+ million VICTREX PEEK seals in use today

75+ million VICTREX PEEK seals in use today

Withstanding higher temperatures and pressures in aggressive chemicals unlocks new and unconventional resources

Driven by limiting climate change and fostering sustainable growth, new opportunities in clean energy become the biggest megatrend for energy industry

Environmental and governmental pressures are mounting for increased energy regulations

PEEK solutions deliver reliability and efficiency in harsh environment

The world‘s primary energy consumption structure is becoming cleaner, low-carbon and diversified, and the transformation is happening faster than previously expected. Given our decades of experience in delivering innovative PEEK thermoplastic solutions for the renewable industry, Victrex understands the need for reliability and efficiency in harsh environments.

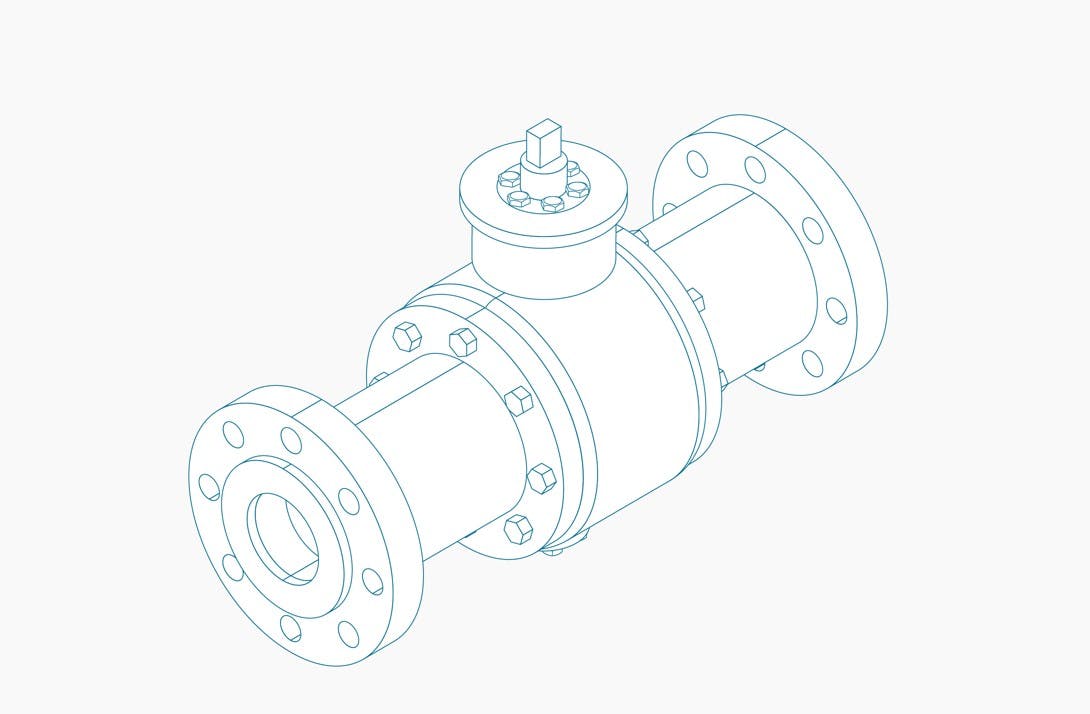

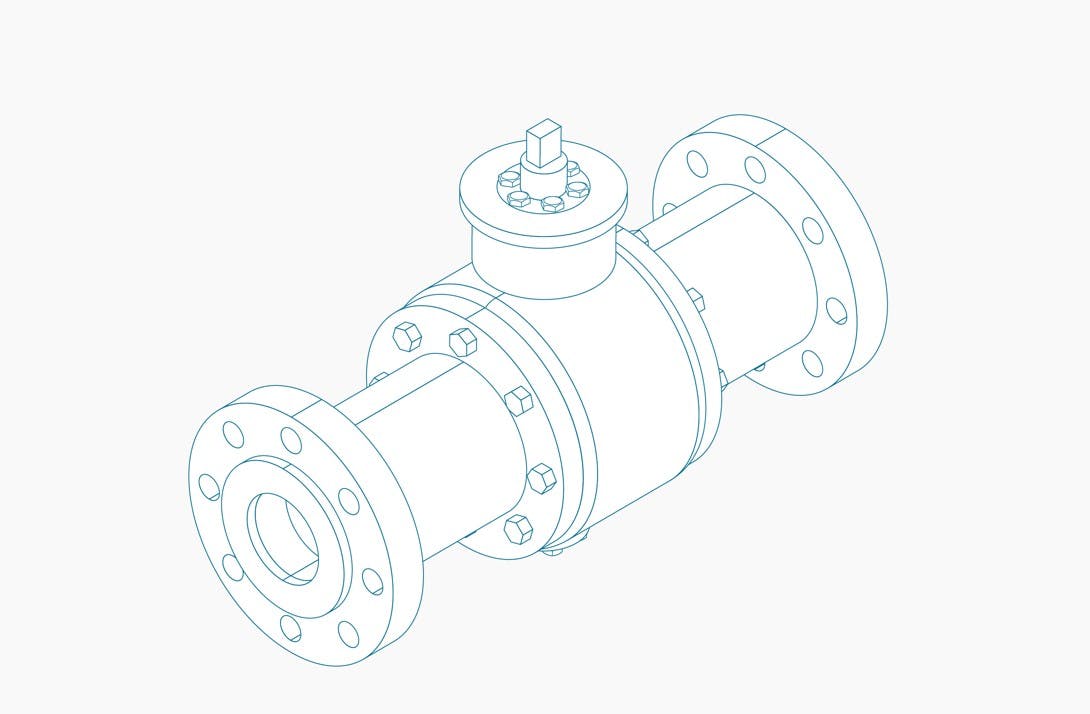

Durable VICTREX PEEK polymer-based solutions can extend the scope of oil and gas exploration and optimize production efficiency in hot, corrosive environments. For over 40 years, Victrex has partners with customers to deliver innovative solutions for the oil and gas market.

Victrex focuses on PEEK & PAEK polymers, considered the world's highest performing thermoplastics

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?