Performance meets processability

Technologies offering reduced costs and increased throughput are a major benefit for the aerospace industry

High fuel costs and preserving the environment are major challenges

Aircraft are expected to be safe with minimal maintenance requirements

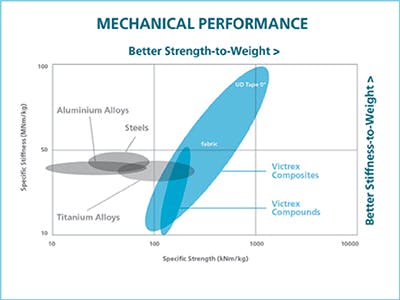

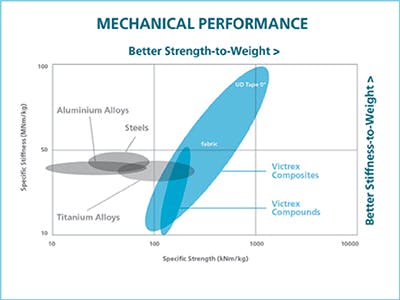

Victrex focuses on PEEK & PAEK polymers, considered the world's highest performing thermoplastics

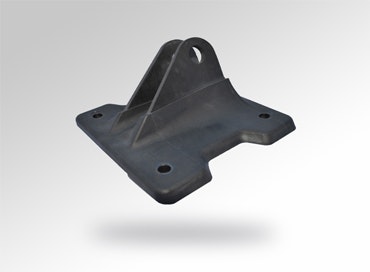

Manufacturing product forms: Pipes, Films, Fibres and Composite tapes

Developing new applications for PEEK, PAEK and Thermoplastic Composites

“The original idea was to create a sort of center of excellence where you could do all of the design and engineering, get tools built, make prototypes and, ultimately, produce commercial parts.”

Jonathan Sourkes -

Victrex Head of Sales for Aerospace

Article from CompositesWorld Magazine

Fluid transport tubing

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?