The combination of an innovative VICTREX PAEK polymer and reinforcing carbon fibres offers mechanical properties that are consistent with the requirements for structural aerospace applications. The resulting VICTREX AE™ 250

LMPAEK-based thermoplastic composite solutions take centre stage in papers and poster presentations at the upcoming ITHEC conference and serve to demonstrate how Polyaryletherketone (PAEK) thermoplastic polymers continue to be an active source of innovation. Forty years after the invention of Polyetheretherketone (PEEK) the best is yet to come.

VICTREX AE 250 LMPAEK process advantages

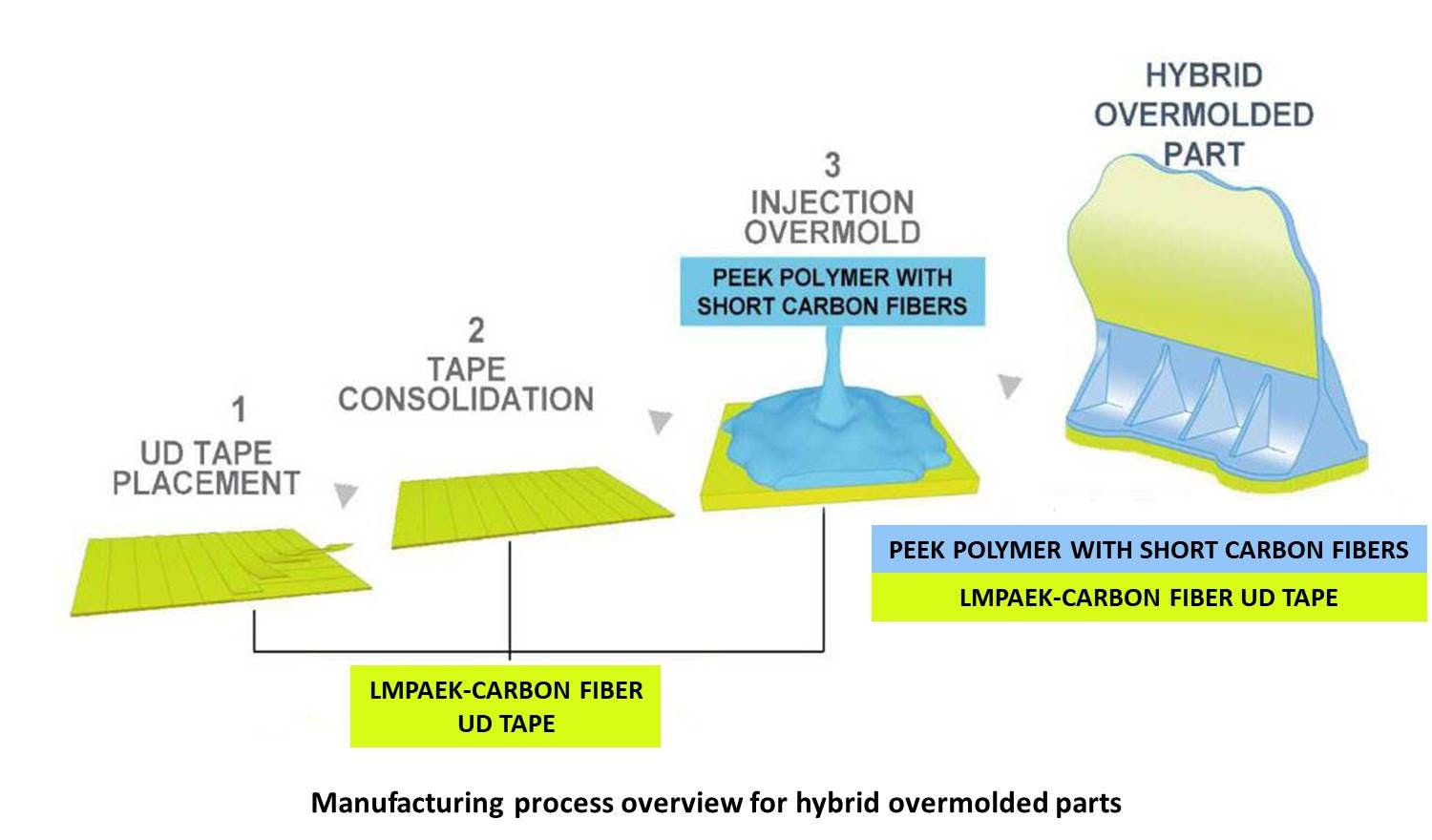

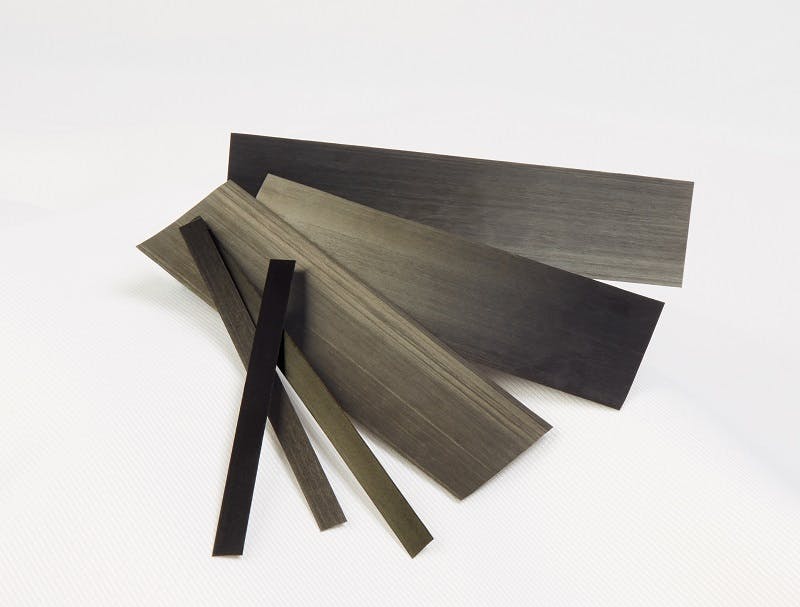

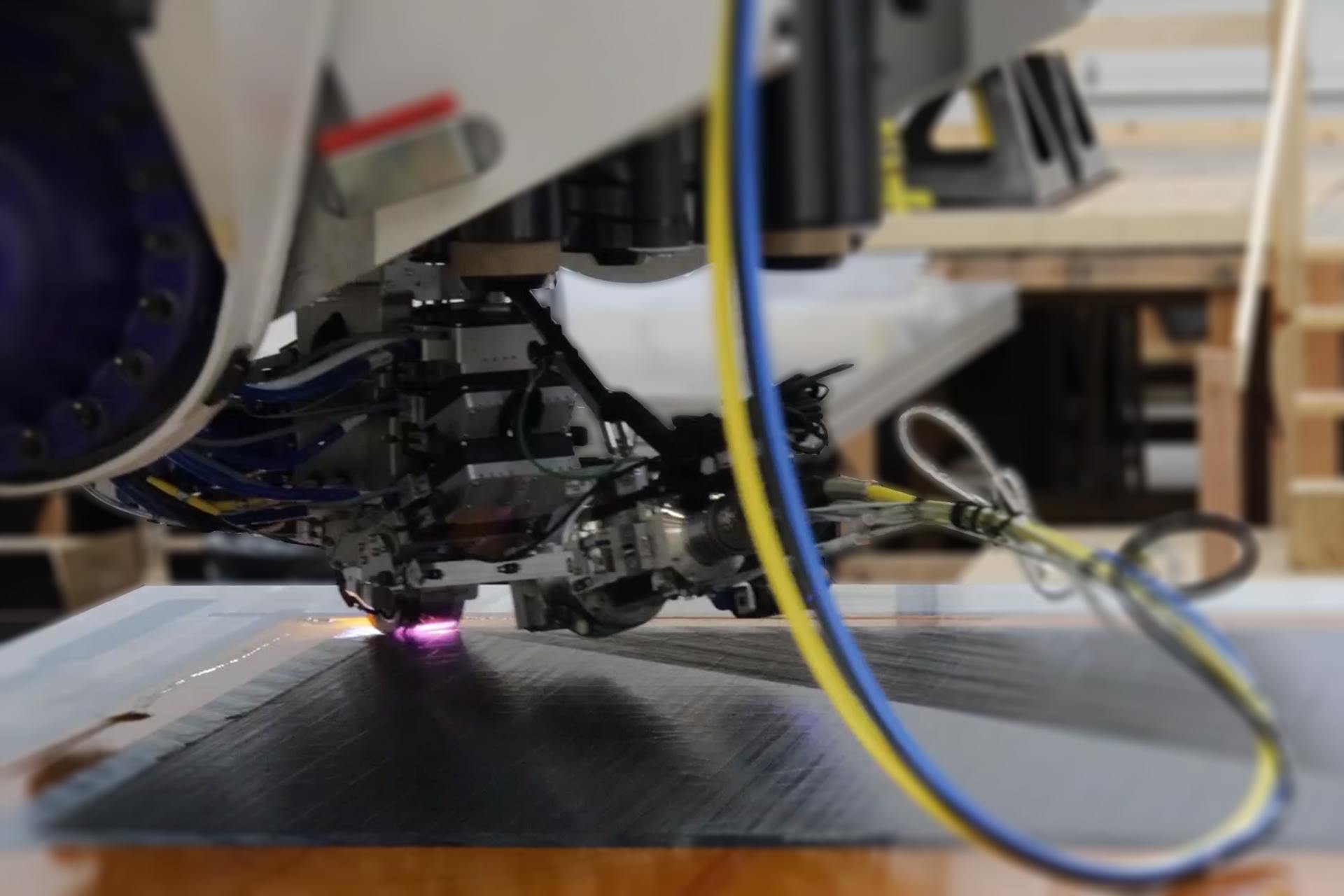

Composites based on traditional PAEK polymers, such as PEEK and related polymers, need to be processed at temperatures in the range of 360 °C-400 °C. “With a melting temperature of 305 °C, our newest LMPAEK polymer processes at between 340 °C-360 °C, allowing composite parts to be manufactured faster and cheaper with added functionality using fast automated lay-up, out of autoclave processing, hot stamping and injection over-moulding”, explains Dr Stuart Green, Market Technology Manager at Victrex, in the run up to the conference. Dr Green will present his research work in a poster illustrating how VICTREX AE 250 LMPAEK unidirectional prepreg tape is compatible with a range of lay-up and consolidation techniques, including automated fibre placement (AFP), oven and press consolidation.

Conference participants can expect an insight into the highly dynamic evolution of composites technology and the wide span of the associated field of research. Other presentations include, for instance, injection forming of gears on high-performance CF-PAEK drive shafts (

Herone GmbH, Germany), the assessment of interface strength in over-moulded structures (

Fibre Institute, Germany), and the developments and future challenges of processing thermoplastic composites (

TenCate Advanced Composites, The Netherlands).

Further information on

ITHEC and the

programme of the

4th International Conference & Exhibition on Thermoplastic Composites”,

October 30-31, 2018, Bremen/Germany.